Hardfacing materials are hard, wear-resistant materials applied on a worn or new component surface by hard-facing technologies such as built-up welding (PTA, laser cladding, oxyacetylene surfacing), spray&fuse welding, infiltration and thermal spraying to reduce wear. These products not only significantly enhance the wear resistance, corrosion resistance, heat resistance, impact resistance and other properties of the component surface, but also serve special functional coatings such as sealing, insulation and heat insulation. It can extend the service life of the components significantly, reduce consumption & production costs, and improve work efficiency.

Hard-Facing Technology

Built-up Welding Technology

Built-up welding is to use gas welding, plasma transfer arc welding (PTA) or electric welding processes to weld metal with wear resistance, corrosion resistance and other special properties onto the surface of workpiece. It is usually used to repair wear and crack parts of the workpiece. Thus the repaired workpiece can be strengthened and have wear resistance, heat resistance, corrosion resistance. It is an economical process for material surface modification. Built-up welding has been widely used in more and more fields, among which oxyacetylene flame welding and plasma arc welding are most widely used.

Oxyacetylene Flame Welding

Oxyacetylene flame welding is the most common method of build-up welding. This process can melt the welding-rod by oxyacetylene flame and coat it onto the surface of the workpiece to form a hard layer. Oxygen, acetylene and flame gun are needed for this method. It also requires that the surface of the workpiece must be cleaned up and the workpiece must be preheated to an appropriate temperature before welding. In addition, it’s important to minimize the weld pool during surfacing, so as to avoid the deposition of tungsten carbide particles to the bottom of the weld layer. Furthermore, if the welding pool is too large, it is easy for the welding layer to have pores.

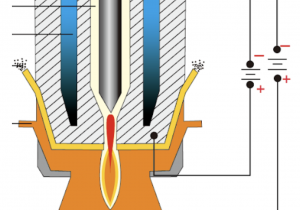

Plasma Transfer Arc Welding

Plasma transfer arc welding (PTA) can be used for processing special valves, drill bits, mining parts, mold, shaft, and others. Although this built-up welding equipment is relatively complex and the cost is relatively high, the thickness of the welding layer can be controlled, and the grains of the welding layer are uniform and neat. Adjusting and controlling the welding parameters can be complex, so the operator must have high operation skills.

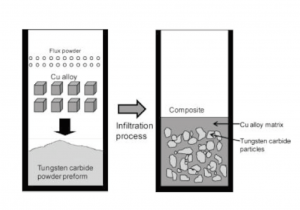

Infiltration Technology

The infiltration technology is a method which relies on the external liquid metal to wet the porous powder body. Under the action of capillary force, the liquid metal flows along the pores between particles until the pores are completely filled. It will form a compact workpiece after infiltration and cooling. This method is commonly used in oil industry to manufacture PDC dill bits.